ELECTRONICS

Laser processing solutions for electronics

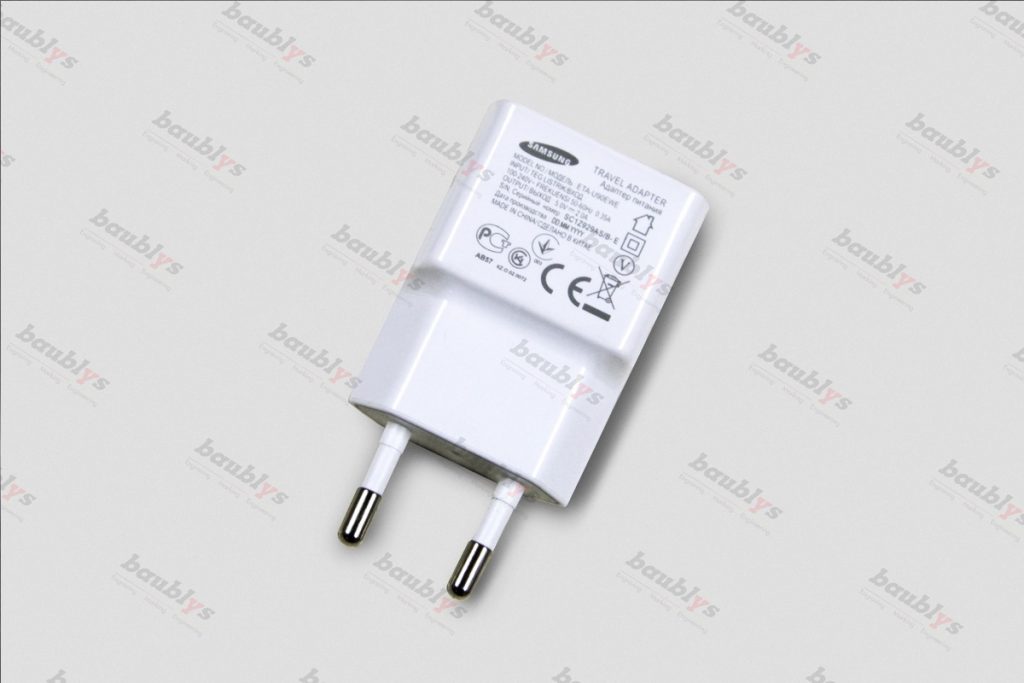

Laser technology has been used in the electronics for a few years now and it has helped many consumer electronics companies to provide better products for their customers.

Laser marking, laser cutting is the most common technology used on electronics, which helps manufacturers improve the efficiency and quality of their product.

-1024x683.jpg)

High quality requirements and absolutely complete information flow in every process step are the requirements in the field of electronics. Circuit boards and electronic components are marked with permanent, solder-resistant and safe machine-readable laser markings, for example a data matrix code.

The laser system can read the information to be inscribed directly from a database, mark it on the component and check it for quality and content through a camera system. With the use of a camera system, the position and orientation can be detected, the caption can be automatically adjusted, and the content and quality can be checked. Thus you achieve high quality assurance as well as high production efficiency.

Fully automated laser systems with automatic loading and unloading of printed circuit boards, for example, guarantee high efficiency and high volume flow.

Possible laser marking methods:

- Annealing

- Marking and cutting foils

- Colored annealing

- Color / anodizing and paint removal

- Surface structuring

- Marking

- Deep engraving

- 3D deep engraving

- Laser cutting

- Foaming

- Carbonization

Some other application examples

More applications on electronics industry

-

- 1D and 2D codes

- Marking of serialnumbers

- Marking logos

- Raw materials and finished products

- Cutting materials

- Marking characters and images

- Automation with conveyor belt, turntable, loading and unloading system or robot

- Marking of printed circuit boards and other electronic components / assemblies / SMD components

Advantages

High efficiency is achieved by an extremely flexible laser marking system, which adapts quickly to changing requirements.

High economic efficiency, identification, traceability, quality assurance through testing with integrated camera, database connection with feedback of the labeling, high quality, durable and permanent marking, optimal and long-lasting readability.