AUTOMOTIVE

Laser processing solutions for automotive

In the area of the automotive industry, high quality, durable and permanent marking ensures the identification and traceability of the products. For years, the automotive industry has relied on Baublys for their automotive production.

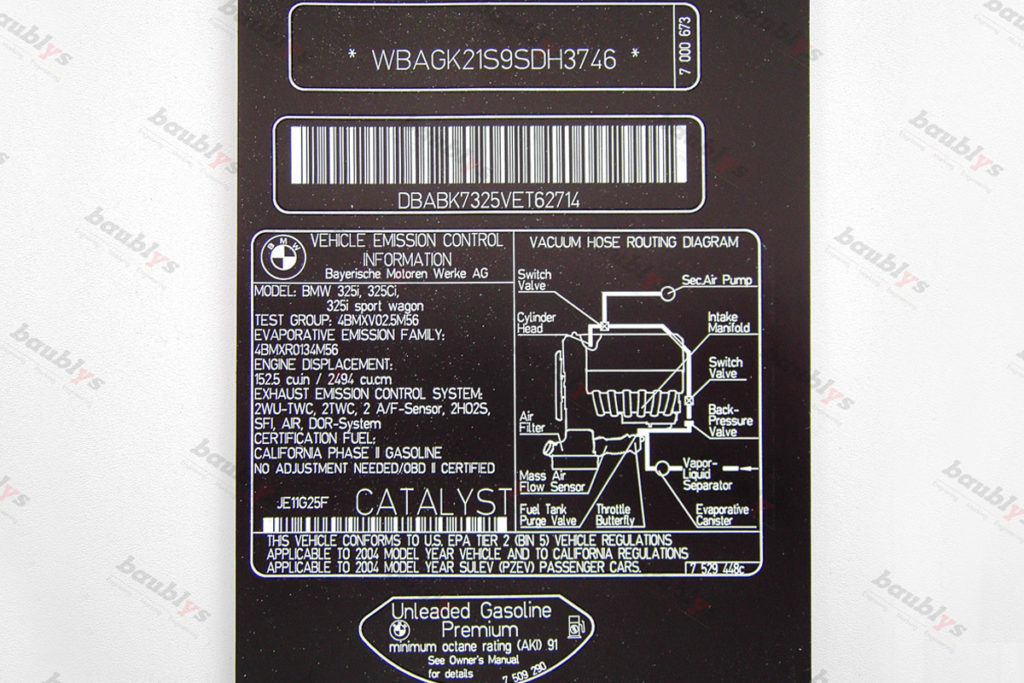

The requirements for the marking of the products can´t be more varied. Starting with the well-known day / night design mark by removing paint on switches, buttons and controls, so that the base material to be backlit becomes visible, for direct inscription of individual nameplates, up to black and white marking on metals.

All labeling requirements can be implemented extremely flexibly with the use of a laser marking system. Continuous serial numbers, various 1D & 2D codes, logos and much more, can be labeled with a single laser marking system individually and also partially or fully automatically on the product.

With the use of a camera system, the position and orientation can be detected, the caption can be automatically adjusted, and the content and quality can be checked. Thus you achieve high quality assurance as well as high production efficiency.

Possible laser marking methods:

- Annealing

- Marking and cutting foils

- Colored annealing

- Color / anodizing and paint removal

- Surface structuring

- Marking

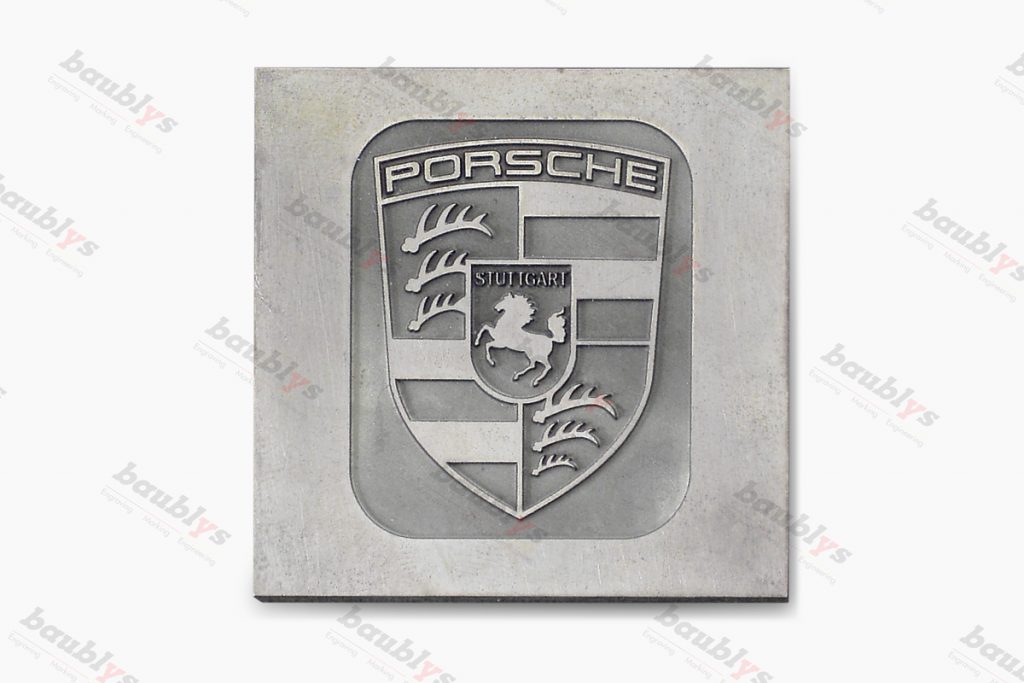

- Deep engraving

- 3D deep engraving

- Laser cutting

- Foaming

- Carbonization

Some other application examples

More applications on automotive industry

- Oiled parts

- Molded

- Black and white marking on metal

- Data Matrix codes

- 1D&2D codes,logos,individual data

- Deep engraving for stamps

- Nameplates

- Marking and cutting of foil

- foaming/carbonization

- Day/night design marking

- Automation with conveyor belt, rotary table or robot

Advantages

High economic efficiency, identification, traceability, quality assurance through testing with integrated camera, database connection with feedback of the labeling, high quality, durable and permanent marking, optimal and long-lasting readability.