PLASTICS

Laser processing solutions for plastics

Our laser marking systems come in a wide variety of wavelengths, power levels and beam profiles which give us the ability to mark a lot of types of material or part. Depending on the type of plastic, the process of laser cutting, laser engraving, and laser etching offer a number of benefits.

-1-1024x683.jpg)

Plastics can be quickly, variably and flexibly applied with different information using a laser system. Some plastics can already be processed with a fiber laser, others by using a UV laser. The UV laseris suitable for almost all plastic and rubber compositions.

The information can be applied by the laser foaming or carbonization on the component. The applications can´t be more versatile. The marking of, for example, panels for household appliances (white goods), cistern, circuit breaker, housing of electronic components and much more.

Laser machines from Baublys can mark a wide variety of plastics including: acrylic, PVC, polyethylene, silicone and more! Not sure which laser suits your needs? We offer a complete risk-free sample testing study to determine the optimal machine and settings for your production.

Possible laser marking methods:

- Annealing

- Marking and cutting foils

- Colored annealing

- Color / anodizing and paint removal

- Surface structuring

- Marking

- Deep engraving

- 3D deep engraving

- Laser cutting

- Foaming

- Carbonization

Our lasers called DracoTM series laser, including IR laser, green laser, UV laser and IR pico-second laser, is the intellectual property of our mother company Han‘s Laser and has acquired innovation patent in United States.

Some other application examples

More applications on plastics industry

-

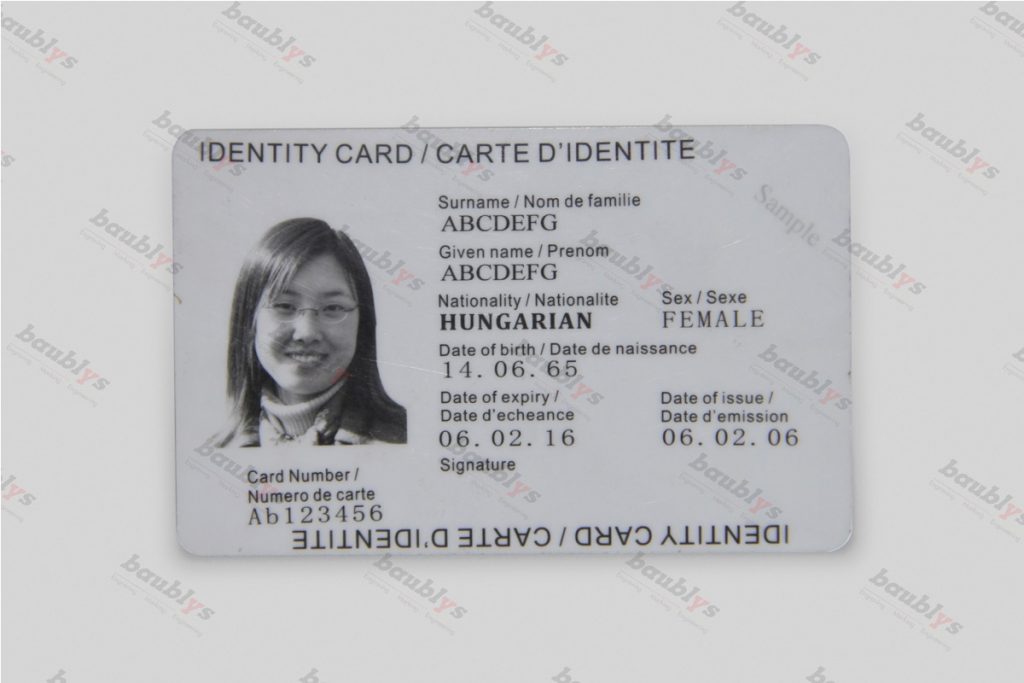

- Marking of plastics and rubber

- Marking of 1D & 2D codes

- Marking information and logos

- Marking consecutive serial numbers

- Marking of raw materials and finished products

- Cutting materials

- Automation with conveyor belt, turntable or robot

Advantages

High efficiency is achieved by an extremely flexible laser marking system, which adapts quickly to changing requirements.

High economic efficiency, identification, traceability, quality assurance through testing with integrated camera, database connection with feedback of the labeling, high quality, durable and permanent marking, optimal and long-lasting readability.